Popular categories

-

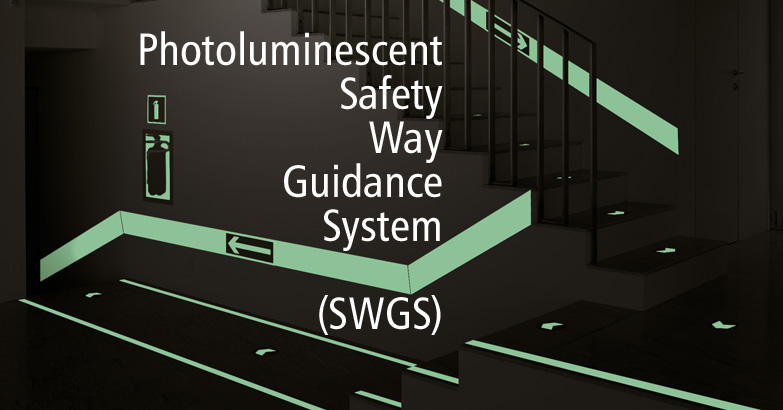

Photoluminescent emergency signs

Photoluminescent emergency signs -

Fire-protection photoluminescent signs

Fire-protection photoluminescent signs -

Photoluminescent signs on sea ships

Photoluminescent signs on sea ships -

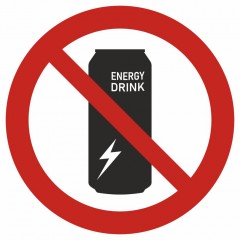

Labour protection and occupational hygiene

Labour protection and occupational hygiene -

Boards and pictograms

Boards and pictograms -

Fire Safety Equipment

Fire Safety Equipment -

Emergency lamps

Emergency lamps -

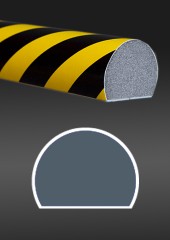

Caution tapes, anti-slip tapes, chains and posts for a plastic chain

Caution tapes, anti-slip tapes, chains and posts for a plastic chain -

Road signs and safety

Road signs and safety